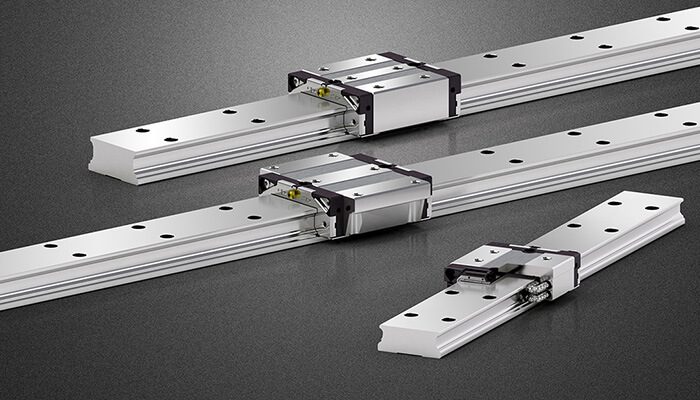

CPC recirculating ball bearing slides offer uncommon technical characteristics, the result of product engineering aimed at offering an innovative system, ensuring perfect interchangeability with existing systems on the market.

The characteristic of the “O” profile of the guide allows a better hold of the loads compared to the guides with “X” profile, especially in the application with lateral cantilever loads.

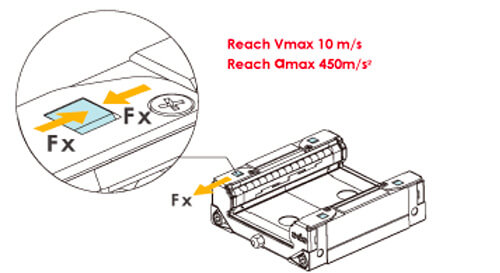

The high technological content, with the optimized contact point of the balls, the integrated internal lubrication (standard) and the front steel plates (standard) to guarantee the plastic heads, allow to reach speeds up to 10m/sec with acceleration of 450 m/sec².

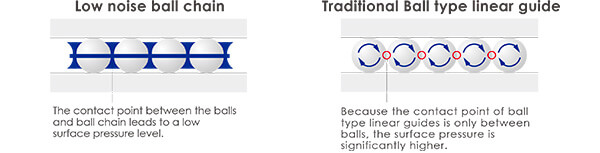

Caged spheres:

The caged balls allow to dampen vibrations at high speeds, drastically reducing the noise.

Protection system:

The total protection of the balls, through the frontal and longitudinal seals, prevents the entry of dirt, allowing a better retention of the lubricating grease, so as to increase the lubrication intervals, and reducing the maintenance of the system.

O-contact type:

The four rows of balls, with one O-contact, make it possible to guarantee the load values in all three directions in the same way.

Patented design for high speed and strong impacts:

The stainless steel L-shaped reinforcement plates with lower locking on the skid help to cover and strengthen the front heads, allowing high speed and strong impact operations with continuous motion reversals.

Patented steel reinforcement plate design:

Using two L-shaped stainless steel reinforcing plates, fixed with screws to the top and bottom of the runner block, increases rigidity and ensures durability of the plastic head, where balls are recirculated.