CPC recirculating ball bearing slides offer uncommon technical characteristics, the result of product engineering that offers an innovative system. The very wide range, from size 15 to size 55 with long and low series trolleys, allows to comply with international application standards.

The characteristic of the “O” profile of the rail allows a better hold of the loads compared to the rails with “X” profile, especially in the application with lateral cantilever loads. The high technological content, with the optimized contact point of the balls, the integrated internal lubrication (standard) and the front steel plates (standard) to guarantee the plastic heads, allow to reach speeds up to 10m/sec with acceleration of 500 m/sec².

In addition, the double lip front seals, the internal and external longitudinal seals (upper and lower) with the possibility of adding as an option the front seals in NBR allow the CPC recirculating ball bearing guides to maximize the performance of the machine even in critical applications, with heavy loads, high speeds and in conditions of extreme dirt.

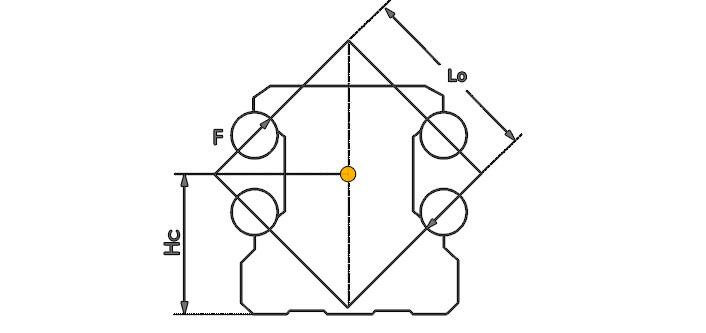

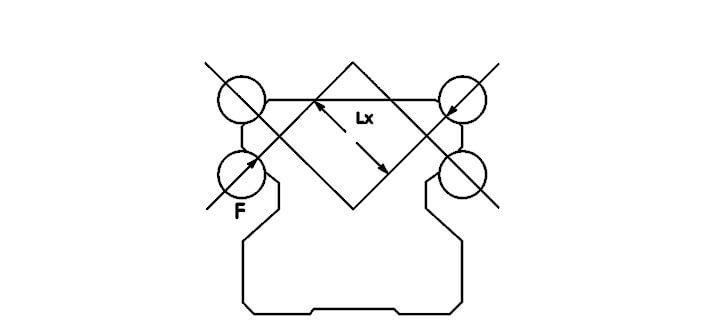

- O-rail profile, with four 45° ball contact points

- Optimized gothic arc ball contact point

- Oversized spheres

- Accuracy grade: N-H-P-SP-UP

- Reagent arm The increased compared to Lx for X-profile guidance

- High torsional stiffness

- High load capacity

- Integrated lubrication pad inside the carriage

- Lubrication nozzles in all directions: frontal-lateral – from above

- Low friction double lip front seals (S)

- Reinforced double lip front seals (B)

- Steel sheet on the heads to protect plastic heads

- Upper and lower internal longitudinal seals (bottom and top)

- NBR seals for particularly hostile environments (option)

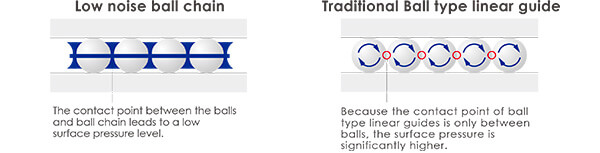

- Caged spheres (option)

- Anti-corrosion surface treatments on carriage and ball guides (option)

- Bottom-hole guides (option)

- Plastic rail mats with metal head (option)

LOWER AND UPPER LONGITUDINAL SEALS

BALL CHAIN SYSTEM

STAINLESS STEEL REINFORCEMENT PLATE

INNER LUBRICATION STORAGE PAD

CPC linear systems offer considerable technical and application advantages, which make them ideal for use in particularly difficult sectors in terms of performance, durability and maintenance.

- Speeds up to 10 m/s

- Acceleration up to 500 m/sec2

- Equivalent loads in all directions

- Low noise level

- Constant and optimized linear flowability

- High efficiency

- High degree of protection

- Total protection with NBR seals

- Trolley strength (with steel front seals)

- Compactness of the carriage (with internal lubrication reservoir)

- Easy lubrication (nozzles in all positions)

- High working autonomy (internal tank)

- Reduced maintenance costs

CPC recirculating ball bearing slides can be used in any industrial sector and are particularly suitable for particularly difficult applications and environments, such as wood, glass, marble, carbon fibre and glass.

- ARC SERIES: for automation

- HRC-ERC SERIES: for heavy duty applications

- ARU: with drilling and threading from below (blind)

- SIZES OF GUIDES AND BLOCK: 15-20-25-30-35-45-55

- TYPE OF BLOCK: M narrow, F flanged

- LENGTH OF BLOCK: L long, N standard, S short

- Number of holes on BLOCK: R with 6 holes

- FRONT SEALS: B low friction, S standard

- PRECISION CLASSES: N normal, H high, P precise, SP super precise, UP ultra-precise

- PRELOAD: VC with backlash, V0 light, V1 medium, V2 heavy